Why Are All Pigging Valves DBB Structures?

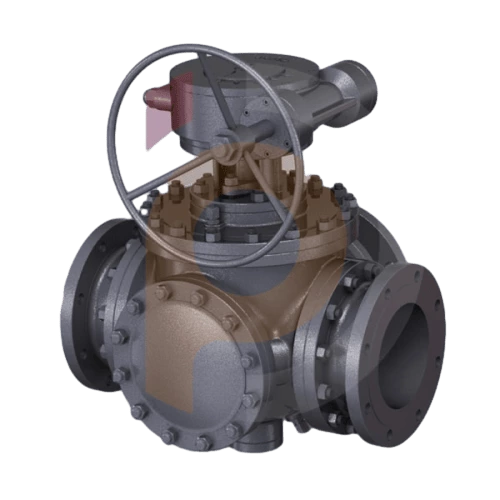

Due to the special operation of the pigging valve, it is essentially different from the ball valve. API 6D ball valves have DBB, DIB-1 , DIB-2 and other structural functions. The pigging valve only has the DBB structural function. DBB has double cutoff and release functions (two sealing pairs can maintain a sealed state at the same time). The valve seat of DBB belongs to a single piston seal. DIB has double isolation and pressure relief (the valve with two valve seat sealing surfaces resists the source pressure through the valve cavity between the pressure relief sealing surfaces in the closed position).

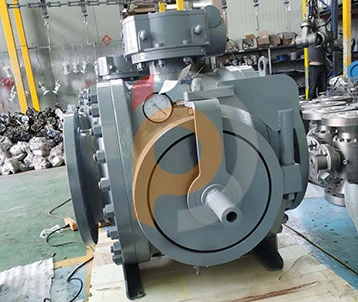

When the pigging valve needs to be used for pigging operation, the pigging valve with DBB function cuts off the pressure from both ends of the valve, releases the pressure in the valve cavity, quickly opens the quick-opening door to load the pig, closes the quick-opening door and opens the pigging valve to allow the pig to enter the pipeline for operation.

If it is a DIB structure pigging valve, a safety valve must be installed. When the pressure in the middle cavity is too high, the safety valve will trip and release the pressure, polluting the environment. When pigging is required, the pressure in the inner cavity of the pigging valve is removed and the DIB structure becomes a DBB structure. That is why all pigging valves are DBB structures.