Brief Analysis Of The Application Fields Of Stainless Steel Valves

Stainless steel valves have entered industrial applications due to their outstanding advantages such as long service life, low rust, and green environmental protection. They have become a must-buy valve product in the pipeline field of various industries. Therefore, before purchasing stainless steel valves, customers must ask the merchants to provide various stainless steel valve production and factory certificates. Spectrometers can also be used for testing. Spectrometers are widely used due to their high precision and wide range of uses. Their application in the field of precious metal and stainless steel valve testing has also developed rapidly in recent years. Some 304 and 316L valves mainly rely on this equipment for testing, which can reduce the purchase of unqualified products.

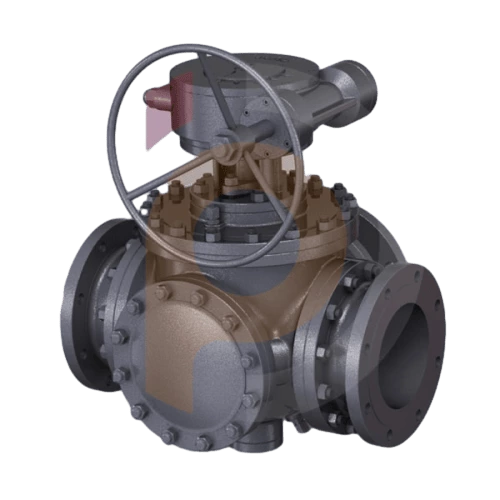

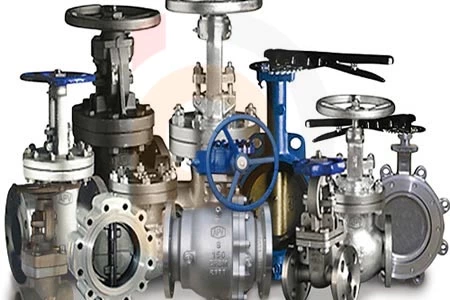

Stainless steel valves are usually used in places where the working medium has a certain degree of corrosiveness, such as corrosive media, food, medicine, oil, liquid metal and chemical products such as radioactive media. In these fields, the ability of any valve material to resist the corrosion of the working medium is relatively limited and is affected by many factors. If the processing technology and heat treatment process used in the manufacturing process are appropriate, the corrosion resistance of this material can be guaranteed. As for the concentrated nitric acid medium with a concentration of >98%, no matter what kind of heat treatment process is used, this steel does not have corrosion resistance. Therefore, when selecting valve materials such as ball valves, gate valves, stop valves and check valves according to the properties of the working medium, it is necessary to simultaneously study the influence of factors such as the concentration and temperature of the medium and the heat treatment process of the material on the corrosion resistance in order to select better steel materials such as 316L, 904 or titanium valves.

With the continuous development of petrochemical industry technology and scale, the requirements for stainless steel valves for petrochemical use are getting higher and higher. In addition to continuing to improve the quality of conventional valves such as J41W stainless steel stop valves, Z41W stainless steel gate valves, etc., especially for corrosive materials, the demand for Q41F stainless steel ball valves is increasing. For example, ethylene cracking units, polyethylene units and polypropylene units in ethylene production, PTA units (purified terephthalic acid), polyester units and polyester spinning units in chemical fiber production, etc. Therefore, efforts should be made to develop corrosion-resistant technology. 316L stainless steel valves have excellent characteristics such as corrosion resistance, high strength, light weight and long service life.

As society progresses, the number of industries increases, and the number of industries that can use stainless steel valve products also increases. New industries and new products will gradually replace cast iron valves, which brings new opportunities for the stainless steel valve industry and a good market development prospect.