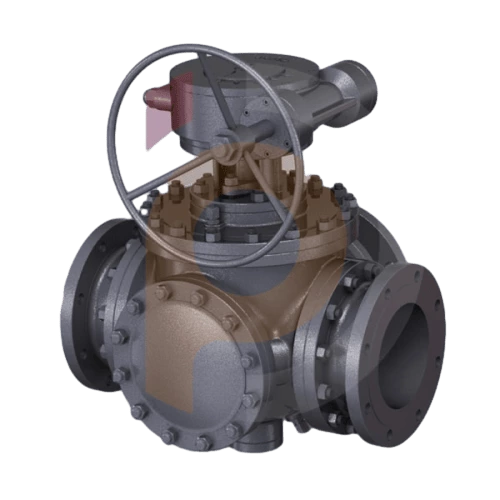

A ball valve is a fluid flow control device that uses a hollow, porous, swingable ball to control the flow of fluid through it. It is in the open position when the hole in the center of the ball is aligned with the flow inlet, and when it is swung 90 degrees by the valve handle, the hole is closed and the fluid stops flowing. When open, the handle is flush with the flow direction, and when closed, the handle is perpendicular to the flow direction, which facilitates visual confirmation of the valve status. The 1/4 rotation to the closed position can be clockwise or counterclockwise.

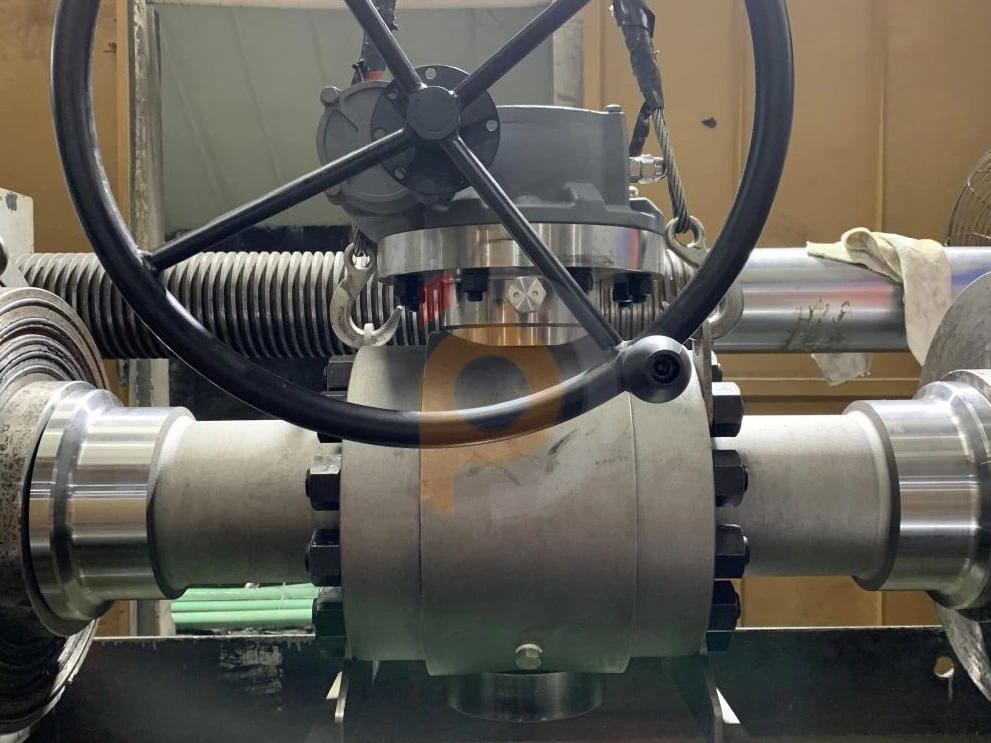

The ball valve is on the pressure test bench, undergoing water pressure sealing test and air pressure sealing test. The cleaning valve test is divided into several steps. The assembled ball valve is hoisted on the valve pressure test machine. The two ends are tightened and sealed by the hydraulic claws on the press. The ball valve is in a half-open state and pressurized to 1.5 times the nominal pressure. No leakage is allowed. Then close the valve and test the valve seal. No leakage is allowed.

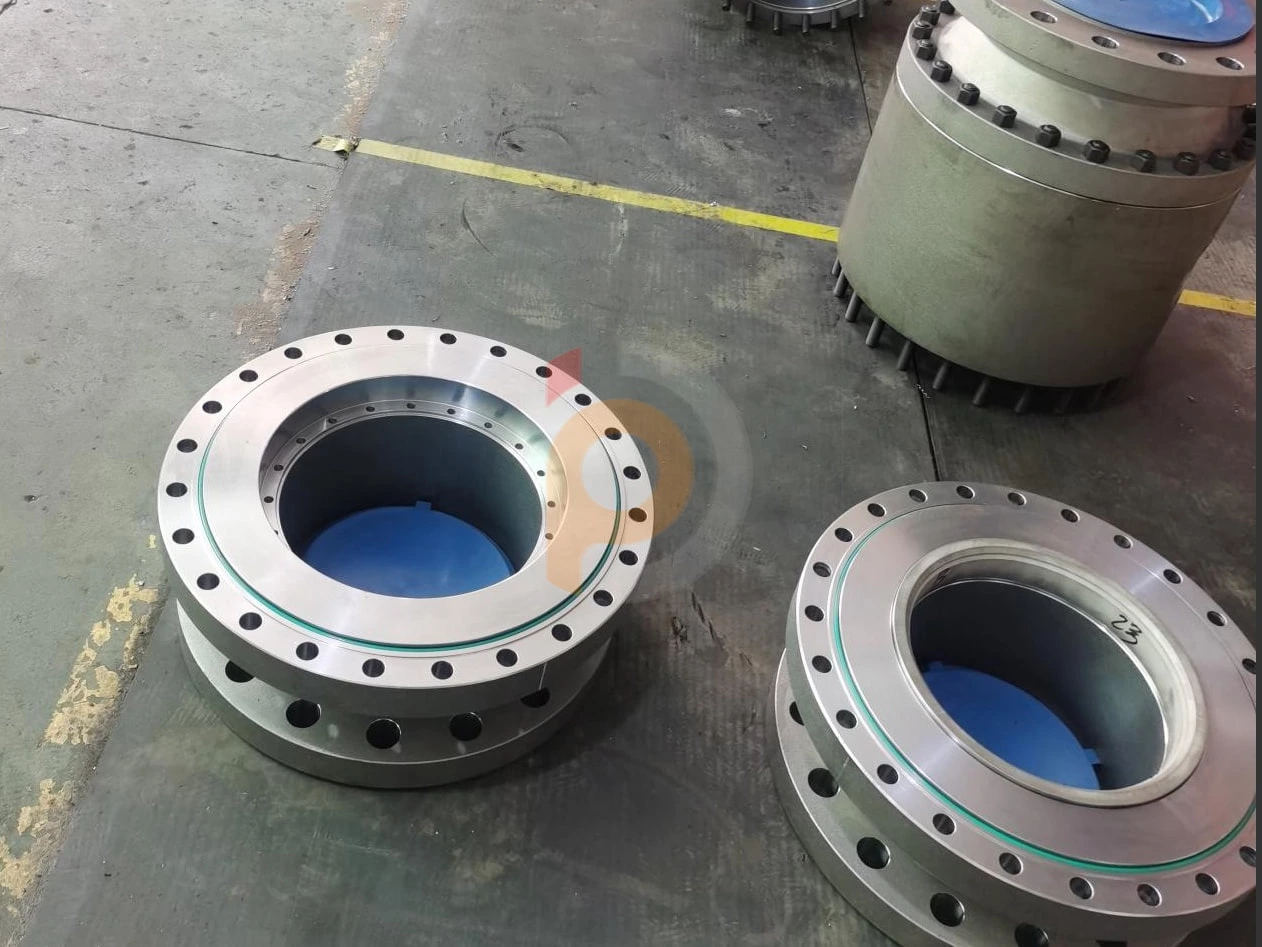

Ball valve, all parts are processed, the parts include valve body, valve cover, side cover, ball, valve stem, lower valve stem, valve seat ring, worm gear drive, bolt and nut standard parts, seals and other accessories. There are the following steps, install the valve seat into the valve body and valve cover, then put the ball into the middle cavity of the valve body, and then use bolts and nuts to combine the valve body and valve cover. Install the upper and lower valve stems, as well as the actuator connection plate, and finally install the worm gear drive, and the ball valve is installed.

The ball valve ball is processed in the workbench of the vertical machining center, and the upper and lower valve stem shaft holes and the upper valve stem milling groove are processed. The ball is completed by the following steps. Make the ball mold, the foundry completes the casting blank, processes the upper and lower shaft holes, and processes the outer diameter of the ball with the upper and lower shaft holes as the center axis. The outer diameter of the ball is ground to ensure the roundness of the ball, and the ball is electroplated and baked with a thickness of 30~75um and the hardness is controlled at about Vickers hardness HV700.

The main parts of the pig valve include the valve body and the valve cover. They have a long manufacturing period and complicated processes. The steps consist of the following steps: making molds, casting blanks in the foundry, rough machining on the machine tool equipment, surface shot blasting, and then fine machining on the CNC lathe and machining center, followed by boring and drilling, and finally polishing and deburring. The main parts are processed.

A Dedicated Customer Team

Our global reach ensures timeliness, cost efficiency and compliance to ensure your timelines are met. As one of the world's leading companies, with extensive experience and expertise in multiple industries!

You are on your way to becoming an industry leader. We can help you build on your past success and prepare you for a bright future.

Complete control over our products enables us to ensure that our customers receive the highest quality product prices and services.