Pipe Cleaning Valve

Product introduction: Pipe cleaning valve (also known as PIG) Pipe cleaning valve can solve the problem that dirt will be deposited or formed on the inner wall of the pipeline during long-term use. These deposited dirt will increase the resistance of the fluid during transportation. When laying a new pipeline, clean the various residues in the pipeline before operation, and apply rust removal and anti-corrosion layer on the inner wall of the pipeline to make the pipeline unobstructed. Application

- Size range

- 2“~16”

- Pressure level

- ASME 150 – 600

- End connection

- RF, RTJ, butt welding, hub end

Product Introduction:

Pipe cleaning valve (also known as PIG) Pipe cleaning valve only needs to solve the problem that the inner wall of the pipeline will deposit or form dirt during long-term use. These deposited dirt deposited on the pipeline wall will increase the resistance of the fluid during transportation. When laying a new pipeline, clean the various residues in the pipe before operation, and apply a rust removal and anti-corrosion layer on the inner wall of the pipeline to make the pipeline unobstructed.

Uses and functions:

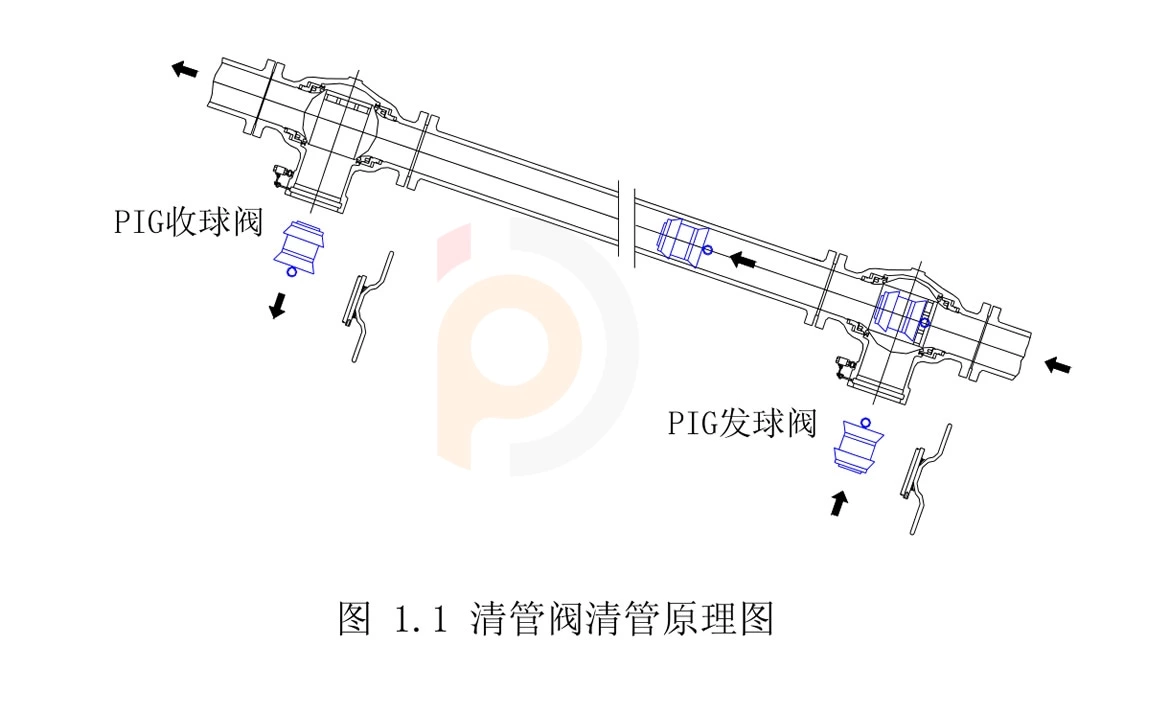

PIG is usually installed in two groups (as shown in Figure 1-1), one group is used for pipe cleaning launch, and the other group is used for pipe cleaning reception. PIG is used for receiving or launching according to the installation upstream or downstream of the pipeline. Compared with the traditional ball-receiving and sending cylinder device or valve group, PIG saves space, has a compact structure and is easy to operate. PIG valve operation process, operate the launch PIG valve to the closed position, so that the upstream and downstream and the double isolation (DBB) ball hole of the middle cavity are on the same axis with the quick opening door. Remove the pressure in the PIG valve cavity, open the quick-opening door, push the pig into the bottom of the valve cavity, then close the quick-opening door, operate the PIG to the open position, and the pig will move forward under the thrust of the medium. After the pig finishes cleaning and reaches the receiving PIG valve, it is blocked in the PIG valve cavity by the fence fixed on the valve seat. Operate the PIG valve to the closed position so that the upstream and downstream and the double isolation (DBB) ball hole in the middle cavity are on the same axis with the quick-opening door. Remove the pressure in the PIG valve cavity, open the quick-opening door and take out the pig.

Features of Jingpai Pipe Cleaning Valve Quick Opening Door:

Jingpai quick opening door has a quick opening door structure with completely independent intellectual property rights, and the quick opening door with a larger diameter is equipped with a rocker hinge device. The quick opening door has an internal pressure protection function. The quick opening door cannot be opened before the pressure is released to prevent accidental opening and staggered opening, reducing the probability of casualties and property losses. The operation is convenient and quick and a patent has been applied for.

Features of Jingpai Removable Pipe Cleaning Barrier:

Jingpai Removable Barrier PIG Valve has multiple uses. This PIG is suitable for the middle section of long-distance pipelines. When the pipeline needs to be cleaned, the removable barrier cleaning valve can replace the severely worn pipe cleaner in the middle section to more effectively clean the stratification and dirt on the inner wall of the pipeline and increase the pipeline flow capacity. Or when the pipe cleaner does not need to be replaced in the middle, the barrier in the removable barrier cleaning valve can be removed. Allow the pipe cleaner to pass through the PIG valve smoothly. It can also reduce the barrier in the pipe cleaning valve to increase the flow resistance coefficient and flow loss, greatly improve the economic value, and apply for a patent.

Pipe cleaning valve type

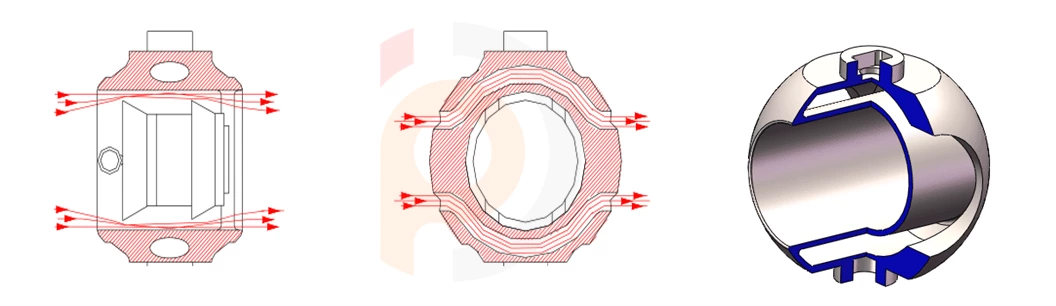

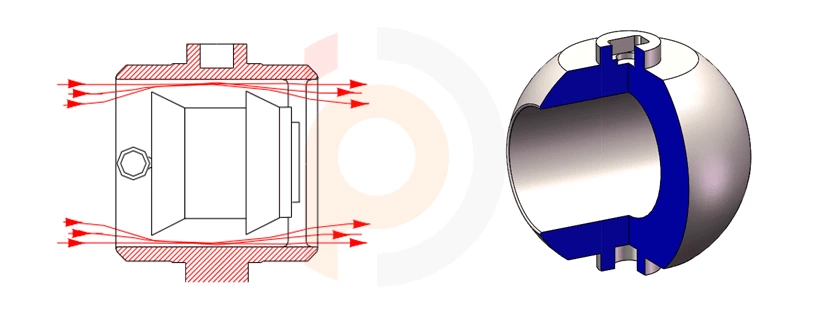

Type B: Pipe cleaning valve type B is a bypass type pipe cleaning valve with a flow area of about 25% of the pipe cross-sectional area. This structure will not cause the PIG to stop flowing even when launching or receiving the pipe cleaning device. Therefore, type B cannot be used as a shut-off valve.

type B

C type

C type pig valve is a standard pig valve. Its ball hole channel area is slightly larger than the inner diameter flow surface of the pipe. When receiving or transmitting, the C type PIG valve will cut off the medium delivery in the pipeline. Therefore, C type can be used as a DBB ball valve.

Storage and handling hoisting suggestions:

No special protection is required before installation. The main thing is to ensure that the accessories installed around the PIG, such as the exhaust valve and vent valve, or the pressure gauge, may cause leakage after collision. It is forbidden to hoist on the valve accessories or actuators. Before installation, ensure that the valve is clean and no foreign matter or garbage is allowed to enter the valve flow channel to prevent damage to the valve sealing door and cause valve leakage.

Valves are prohibited from being stacked in the open air. Long-term storage requires regular inspection. The machined surfaces without spray coating exposed to the atmosphere should be coated with anti-rust grease. Covers are added to both ends of the valve channel to prevent foreign matter from entering. When storing, the valve should be fully opened to avoid damaging the ball surface. The valve should be operated either to fully open or fully closed. The valve cannot be in a half-open position for a long time. The valve can be installed and used outdoors.

Note:

Each PIG valve can be used as a pigging ball valve or a pigging ball valve, but the installation direction of the pigging valve must be distinguished during installation. When used as a pigging ball valve, the end with the fence on the valve seat must be installed at the upstream end of the pipeline. When used as a pigging ball valve, the end of the valve seat with the fence must be installed at the downstream end of the pipeline. When used as a pigging ball valve, a dirt collection container can also be installed in front of the PIG valve and equipped with a receiver/transmitter, which will indicate when the pigging is successful.

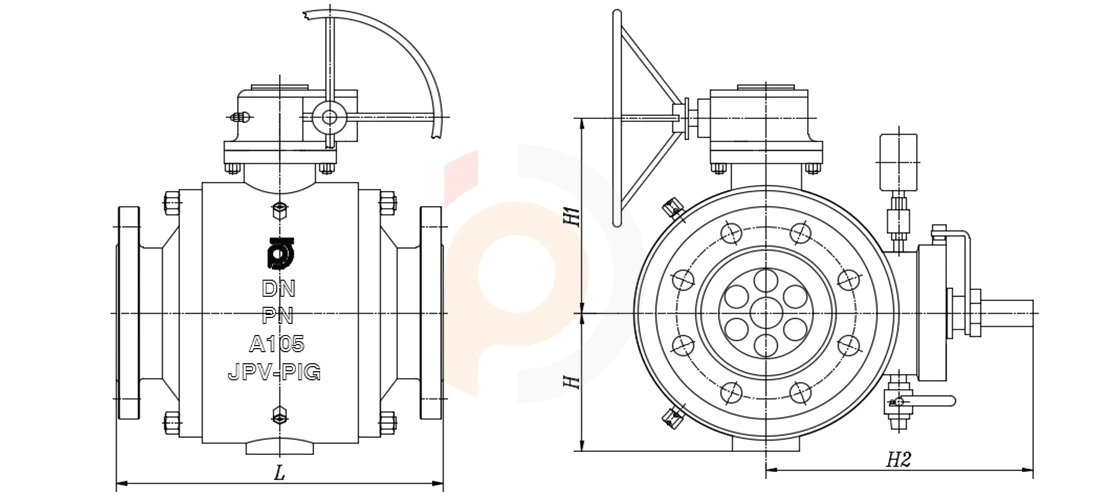

| size | class150 | class300 | class600 | class900 | ||||||||||||

| Nominal pipe size | L | H | H1 | H2 | L | H | H1 | H3 | L | H | H1 | H2 | L | H | H1 | H2 |

| 2 | 310 | 145 | 194 | 180 | 310 | 145 | 194 | 180 | 325 | 145 | 194 | 180 | 348 | 145 | 194 | 180 |

| 3 | 362 | 162 | 213 | 190 | 362 | 162 | 213 | 190 | 375 | 162 | 213 | 190 | 387 | 162 | 162 | 302 |

| 4 | 445 | 186 | 255 | 212 | 445 | 186 | 255 | 212 | 460 | 186 | 255 | 212 | 483 | 186 | 186 | 320 |

| 6 | 520 | 241 | 308 | 277 | 520 | 241 | 308 | 277 | 562 | 241 | 308 | 277 | 590 | 568 | 568 | 583 |

| 8 | 724 | 590 | 831 | 785 | 724 | 594 | 831 | 785 | 818 | 594 | 831 | 785 | 889 | 626 | 847 | 788 |

| 10 | 898 | 663 | 879 | 813 | 898 | 663 | 879 | 813 | 943 | 663 | 879 | 813 | 980 | 663 | 906 | 847 |

| 12 | 1035 | 745 | 990 | 886 | 1035 | 745 | 990 | 886 | 1068 | 745 | 990 | 886 | 1194 | 914 | 990 | 886 |

| 16 | 1372 | 1233 | 1060 | 973 | 1372 | 1232 | 1060 | 973 | 1372 | 1232 | 985 | 973 | ||||