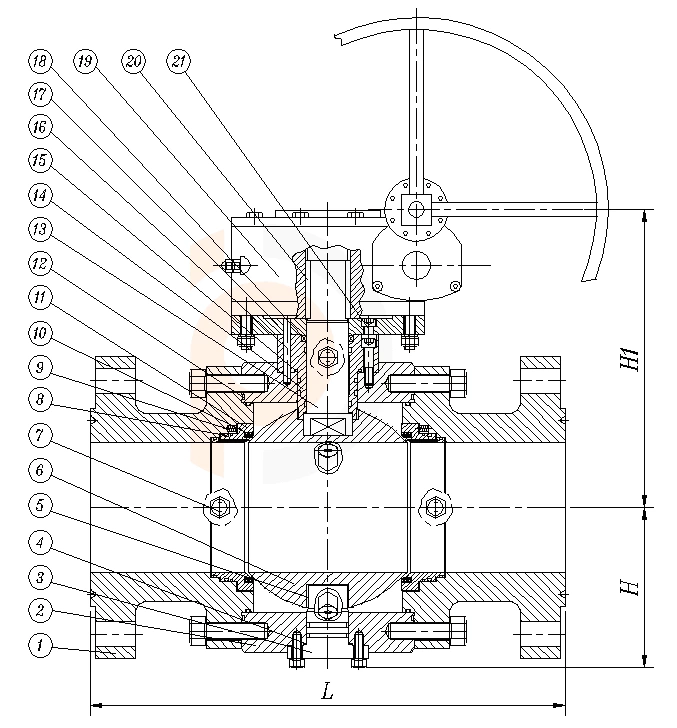

Forged Steel Ball Valve

The working principle of forged steel ball valve is to open or close the valve by rotating the valve stem. It is usually a full-bore ball valve with a 90-degree angle switch. It is light, small in size, can be made into a large diameter, has reliable sealing, simple structure, and convenient maintenance. The sealing surface and the spherical surface are often in a closed state and are not easily eroded by the medium. It is widely used in various industries. Forged steel ball valve classification: low-pressure forged steel ball valve, high-pressure forged steel ball valve.

- Size range

- 2“~40”

- Pressure level

- ASME 150 – 2500

- End connection

- RF、RTJ、对焊、轮毂端部

| Serial number | Name | Serial number | Name |

| 1 | Valve cover | 13 | Valve stem |

| 2 | Valve body | 14 | Stuffing box |

| 3 | Lower cover | 15 | Sealing pad |

| 4 | Sealing pad | 16 | Pin |

| 5 | Sliding bearing | 17 | Connecting plate |

| 6 | Ball | 18 | Packing |

| 7 | Grease injection valve | 19 | Turbine box |

| 8 | O-ring | 20 | Key |

| 9 | Spring | 21 | Hexagon socket |

| 10 | Valve seat support ring | 22 | |

| 11 | Valve seat | 23 | |

| 12 | Sealing gasket | 24 | |

| Technical requirements | |||

| Design and manufacturing standards | API 6d | ||

| Structural length standard | ASME B16.10 | ||

| Flange connection standard | ASME B16.5/B16.47-A | ||

| Inspection and test standards | API 6d | ||

Dimensions:

| Size | Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 | Class 2500 | ||||||||||||

| Nominal pipe size | L | H | H1 | L | H | H1 | L | H | H1 | L | H | H1 | L | H | H1 | L | H | H1 |

| 2 | 178 | 138 | 180 | 216 | 130 | 180 | 292 | 130 | 172 | 368 | 136 | 193 | 368 | 150 | 193 | 451 | 121 | 230 |

| 3 | 203 | 150 | 190 | 283 | 150 | 190 | 356 | 150 | 205 | 381 | 158 | 302 | 470 | 168 | 270 | 578 | 146 | 287 |

| 4 | 229 | 170 | 212 | 305 | 170 | 212 | 432 | 170 | 274 | 457 | 180 | 320 | 546 | 176 | 275 | 673 | 164 | 331 |

| 6 | 394 | 183 | 277 | 403 | 180 | 277 | 559 | 183 | 283 | 610 | 187 | 320 | 705 | 203 | 325 | 914 | 220 | 394 |

| 8 | 457 | 216 | 301 | 502 | 217 | 308 | 660 | 223 | 342 | 737 | 226 | 365 | 832 | 248 | 486 | 1022 | 312 | 488 |

| 10 | 533 | 260 | 359 | 568 | 265 | 381 | 787 | 270 | 393 | 838 | 280 | 495 | 991 | 297 | 535 | 1270 | 425 | 600 |

| 12 | 610 | 287 | 419 | 648 | 307 | 429 | 838 | 310 | 522 | 965 | 329 | 600 | 1130 | 357 | 610 | 1422 | 629 | 872 |

| 14 | 686 | 338 | 460 | 762 | 338 | 460 | 889 | 340 | 551 | 1029 | 390 | 625 | 1257 | 383 | 664 | |||

| 16 | 762 | 375 | 494 | 838 | 375 | 581 | 991 | 378 | 637 | 1130 | 407 | 675 | 1384 | 435 | 700 | |||

| 18 | 864 | 402 | 521 | 914 | 414 | 674 | 1092 | 418 | 683 | 1219 | 526 | 715 | 1537 | 507 | 763 | |||

| 20 | 914 | 427 | 656 | 911 | 450 | 713 | 1194 | 451 | 719 | 1321 | 600 | 750 | 1664 | 586 | 856 | |||

| 24 | 1067 | 518 | 795 | 1143 | 531 | 850 | 1397 | 539 | 823 | 1549 | 700 | 800 | 1816 | 632 | 925 | |||

| 26 | 1143 | 535 | 870 | 1245 | 543 | 905 | 1448 | 548 | 893 | 1658 | 718 | 917 | 2045 | 675 | 1111 | |||

| 28 | 1245 | 542 | 935 | 1346 | 556 | 958 | 1549 | 565 | 950 | 1753 | 742 | 986 | ||||||

| 30 | 1295 | 605 | 1010 | 1397 | 620 | 1035 | 1651 | 620 | 1035 | 1880 | 770 | 1066 | ||||||

| 32 | 1372 | 650 | 1060 | 1524 | 666 | 1087 | 1778 | 666 | 1087 | 2032 | 810 | 1120 | ||||||

| 34 | 1473 | 650 | 1077 | 1626 | 681 | 1104 | 1930 | 682 | 1104 | 2159 | 860 | 1137 | ||||||

| 36 | 1524 | 700 | 1115 | 1727 | 718 | 1143 | 2083 | 718 | 1143 | 2286 | 739 | 1177 | ||||||

| 40 | 1727 | 865 | 1400 | 1930 | 887 | 1435 | 2337 | 887 | 1435 | |||||||||

The above data is for reference only, the actual product shall prevail!