Stainless steel valves have entered the industrial application due to their long service life, rust-free, green environmental protection and other advantages. They have become a must-have valve product in the pipeline industry of all industries. Therefore, customers must require various businesses before purchasing stainless steel valves. The production and delivery certificate of stainless steel valves can also be detected by spectrometer. The spectrometer has been widely used due to its high precision and wide range of applications. Its application in the field of precious metal and stainless steel valve detection has also developed rapidly in recent years. Some 304 316L valves are mainly dependent on the equipment to detect, which can reduce the purchase of unqualified products.

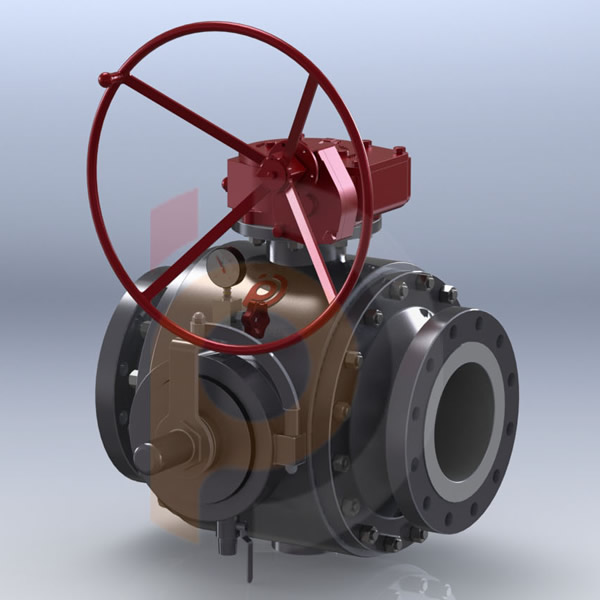

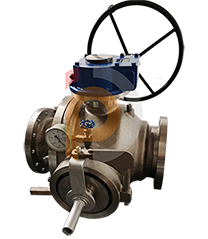

Stainless steel valves are commonly used in applications where the working medium is corrosive, such as corrosive media, foods, pharmaceuticals, oils, liquid metals, and radioactive media. Any of these valve materials are resistant to working media corrosion. Capabilities are relatively limited and subject to many factors. If the processing technology and heat treatment process used in the manufacturing process are proper, the corrosion resistance of the material is ensured. As for the concentrated nitric acid medium having a concentration of >98%, the steel has no corrosion resistance regardless of the heat treatment process. Therefore, when selecting valve materials such as ball valves, gate valves, globe valves, and check valves according to the nature of the working medium, it is necessary to simultaneously study the effects of various factors such as the concentration of the medium, the temperature, and the heat treatment process of the material on the corrosion resistance. Good steel materials such as 316L, 904 or titanium valves.

With the continuous development of petrochemical industry technology and scale, the requirements for petrochemical stainless steel valves are getting higher and higher, in addition to continue to improve the quality of conventional valves such as J41W stainless steel globe valves, Z41W stainless steel gate valves, etc., especially for corrosive materials Q41F stainless steel Ball valves require more and more, such as ethylene cracking equipment, polyethylene equipment and polypropylene equipment in ethylene production, PTA equipment (fine terephthalic acid) in chemical fiber production, polyester equipment and polyester spinning equipment, etc. In an effort to develop corrosion-resistant technology, 316L stainless steel valves are characterized by corrosion resistance, high strength, light weight and long service life.

The society is increasing in the progressive industry, and the industry that can use stainless steel valve products is also increasing. New industries and new products will gradually replace cast iron valves, which will bring new opportunities for the stainless steel valve industry. The market has good development prospects.

中文

中文