|

NO |

Part Name |

NO |

Part Name |

|

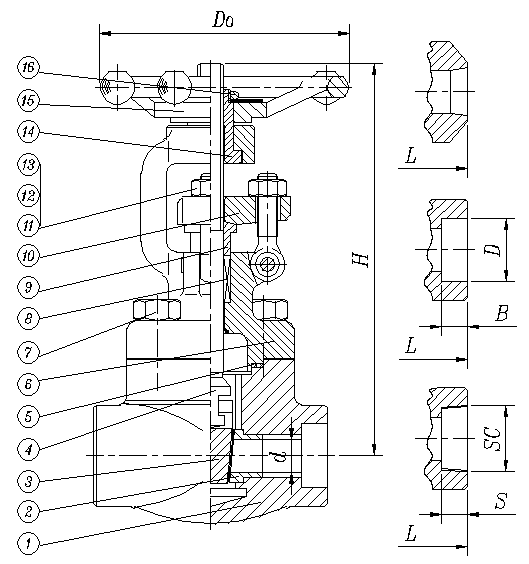

1 |

Body |

12 |

Eyebolts |

|

2 |

Seat ring |

13 |

Nut |

|

3 |

Disc |

14 |

Stem nut |

|

4 |

Stem |

15 |

Handwheel |

|

5 |

Gasket |

16 |

Lock nut |

|

6 |

Bonnet |

17 |

|

|

7 |

Hex bolt |

18 |

|

|

8 |

Packing |

19 |

|

|

9 |

Gland |

20 |

|

|

10 |

Gland flange |

21 |

|

|

11 |

Pin |

22 |

|

|

Technical Requirements |

|||

|

DeSign And Manufacture |

API 602 |

||

|

Face To Face |

Manufacturer's standard |

||

|

Conneciton End |

ASMEB1.20.1/ASME B16.25 |

||

|

Inspection And Test |

API 598 |

||

Dimensions data: Forged steel gate valve

|

NPS DN |

Unit |

L |

d |

SW |

SC |

H (Open) |

Do |

WT (kg) |

||

|

|

|

|

|

D |

B |

NPT |

S |

|

|

|

|

3/8 10 |

In mm |

3.12 79 |

0.394 10 |

0.693 17.6 |

0.378 9.6 |

3/8 |

0.535 13.6 |

6.0 151 |

4.0 100 |

4 |

|

1/2 15 |

In mm |

3.12 79 |

0.394 10 |

0.858 21.8 |

0.378 9.6 |

1/2 |

0.535 13.6 |

6.0 151 |

4.0 100 |

4 |

|

3/4 20 |

mm |

2.63 92 |

0.531 13.5 |

1.067 27.1 |

0.5 12.7 |

3/4 |

0.547 13.9 |

6.25 158 |

4.0 100 |

4.3 |

|

1 25 |

In mm |

4.38 111 |

0.709 18 |

1.331 33.8 |

0.5 12.7 |

1 |

0.681 17.3 |

7.25 185 |

5.0 125 |

6.6 |

|

11/4 32 |

In mm |

4.75 120 |

0.945 24 |

1.677 42.6 |

0.5 12.7 |

11/4 |

0.709 18 |

9.38 239 |

6.25 160 |

9.5 |

|

11/2 40 |

In mm |

4.75 120 |

1.181 30 |

1.917 48.7 |

0.5 12.7 |

11/2 |

0.724 18.4 |

9.5 243 |

6.25 160 |

11 |

|

2 50 |

In mm |

5.5 140 |

1.437 36.5 |

2.406 61.1 |

0.626 15.9 |

2 |

0.756 19.2 |

11.0 279 |

7.0 180 |

14.5 |

The above data is for reference only, subject to actual product

|

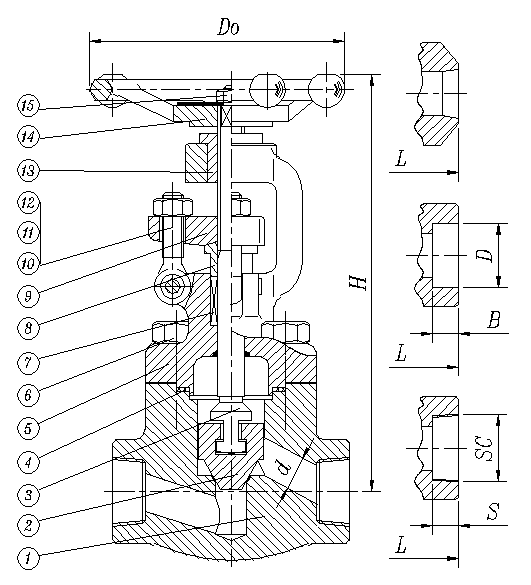

NO |

Part Name |

NO |

Part Name |

|

1 |

Body |

12 |

Nut |

|

2 |

Disc |

13 |

Stem nut |

|

3 |

Stem |

14 |

Handwheel |

|

4 |

Gasket |

15 |

Nut |

|

5 |

Bonnet |

16 |

|

|

6 |

Hex bolt |

17 |

|

|

7 |

Packing |

18 |

|

|

8 |

Gland |

19 |

|

|

9 |

Gland flange |

20 |

|

|

10 |

Pin |

21 |

|

|

11 |

Eyebolts |

22 |

|

|

Technical Requirements |

|||

|

DeSign And Manufacture |

API 602 |

||

|

Face To Face |

Manufacturer's standard |

||

|

Conneciton End |

ASMEB1.20.1/ASME B16.25 |

||

|

Inspection And Test |

API 598 |

||

Dimensions data: Forged steel globe valve

|

NPS DN |

Unit |

L |

d |

SW |

SC |

H (Open) |

Do |

WT (kg) |

||

|

|

|

|

|

D |

B |

NPT |

S |

|

|

|

|

3/8 10 |

In mm |

3.12 79 |

0.354 9 |

0.693 17.6 |

0.378 9.6 |

3/8 |

0.535 13.6 |

6.0 151 |

4.0 100 |

2.8 |

|

1/2 15 |

In mm |

3.12 79 |

0.354 9 |

0.858 21.8 |

0.378 9.6 |

1/2 |

0.535 13.6 |

6.0 151 |

4.0 100 |

3.4 |

|

3/4 20 |

In mm |

2.63 92 |

0.512 13 |

1.067 27.1 |

0.5 12.7 |

3/4 |

0.547 13.9 |

6.25 158 |

4.0 100 |

4.7 |

|

1 25 |

In mm |

4.38 111 |

0.689 17.5 |

1.331 33.8 |

0.5 12.7 |

1 |

0.681 17.3 |

8 203 |

5.0 125 |

9.2 |

|

11/4 32 |

In mm |

4.75 120 |

0.906 23 |

1.677 42.6 |

0.5 12.7 |

11/4 |

0.709 18 |

8.88 224 |

6.25 160 |

10.5 |

|

11/2 40 |

In mm |

4.75 120 |

1.142 29 |

1.917 48.7 |

0.5 12.7 |

11/2 |

0.724 18.4 |

10.5 260 |

6.25 160 |

13.3 |

|

2 50 |

In mm |

5.5 140 |

1.378 35 |

2.406 61.1 |

0.626 15.9 |

2 |

0.756 19.2 |

11.88 300 |

7.0 180 |

18.9 |

The above data is for reference only, subject to actual product

|

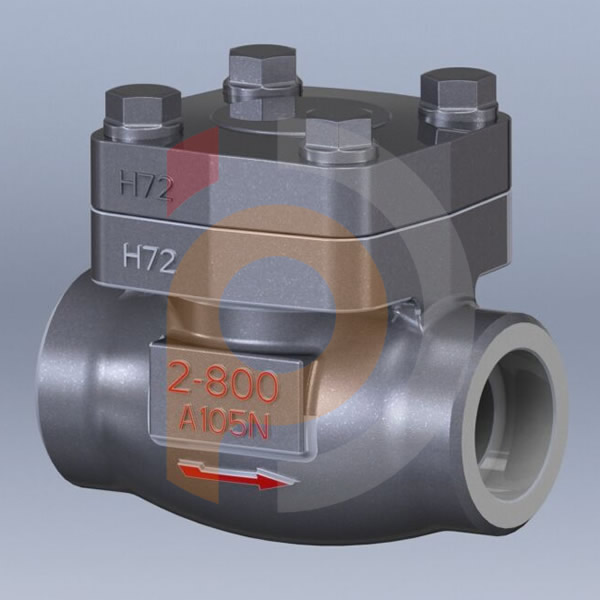

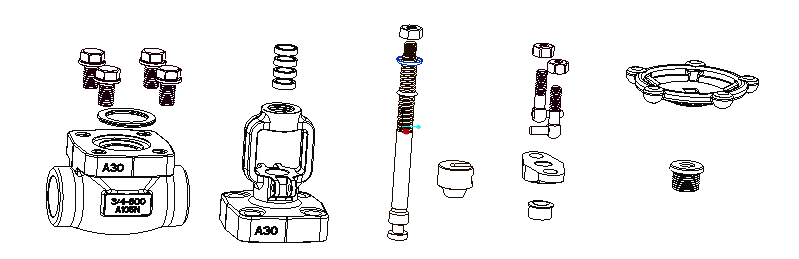

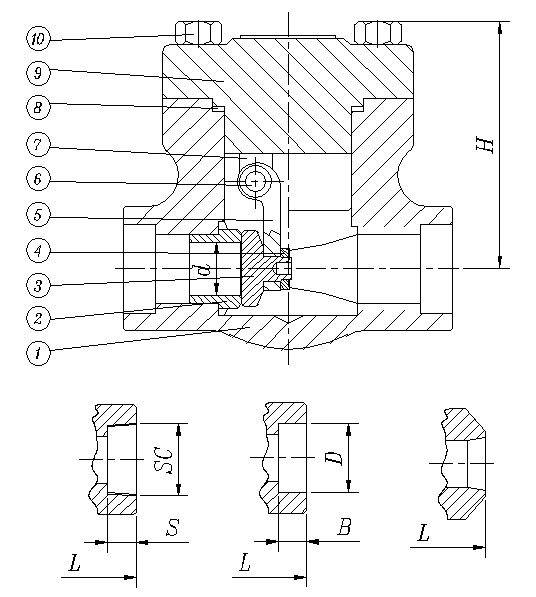

NO |

Part Name |

NO |

Part Name |

|

1 |

Body |

12 |

|

|

2 |

Seat ring |

13 |

|

|

3 |

Disc |

14 |

|

|

4 |

Nut |

15 |

|

|

5 |

Arm |

16 |

|

|

6 |

Pin |

17 |

|

|

7 |

Hook |

18 |

|

|

8 |

Gasket |

19 |

|

|

9 |

Bonnet |

20 |

|

|

10 |

Hex bolt |

21 |

|

|

11 |

|

22 |

|

|

Technical Requirements |

|||

|

DeSign And Manufacture |

API 602 |

||

|

Face To Face |

Manufacturer's standard |

||

|

Conneciton End |

ASMEB1.20.1/ASME B16.25 |

||

|

Inspection And Test |

API 598 |

||

Dimensions data: Forged steel check valve

|

NPS DN |

Unit |

L |

d |

SW |

SC |

H |

WT (kg) |

||

|

|

|

|

|

D |

B |

NPT |

S |

|

|

|

3/8 10 |

In mm |

3.12 79 |

0.354 9 |

0.693 17.6 |

0.378 9.6 |

3/8 |

0.535 13.6 |

6.0 151 |

2.8 |

|

1/2 15 |

In mm |

3.12 79 |

0.354 9 |

0.858 21.8 |

0.378 9.6 |

1/2 |

0.535 13.6 |

6.0 151 |

3.4 |

|

3/4 20 |

In mm |

2.63 92 |

0.512 13 |

1.067 27.1 |

0.5 12.7 |

3/4 |

0.547 13.9 |

6.25 158 |

4.7 |

|

1 25 |

In mm |

4.38 111 |

0.689 17.5 |

1.331 33.8 |

0.5 12.7 |

1 |

0.681 17.3 |

8 203 |

9.2 |

|

11/4 32 |

In mm |

4.75 120 |

0.906 23 |

1.677 42.6 |

0.5 12.7 |

11/4 |

0.709 18 |

8.88 224 |

10.5 |

|

11/2 40 |

In mm |

4.75 120 |

1.142 29 |

1.917 48.7 |

0.5 12.7 |

11/2 |

0.724 18.4 |

10.5 260 |

13.3 |

|

2 50 |

In mm |

5.5 140 |

1.378 35 |

2.406 61.1 |

0.626 15.9 |

2 |

0.756 19.2 |

11.88 300 |

18.9 |

The above data is for reference only, subject to actual product

中文

中文